In the always-changing ways cars are made, 3D printing technology has brought a new generation of chances. One of the most amazing uses of 3D printing in the car business is making special parts for cars. This new technology is changing the usual ways things are made, giving never-before-seen levels of ease and getting stuff done quickly while saving money.

The Evolution of Automotive Manufacturing:

In the past, making car parts was hard and took a long time. Making things in large amounts, while helpful for making many items at a time, usually didn’t work well when it came to changing designs. Old ways of making things, like injection molding and CNC machining, could not make complex parts very well, especially for fancy or special cars.

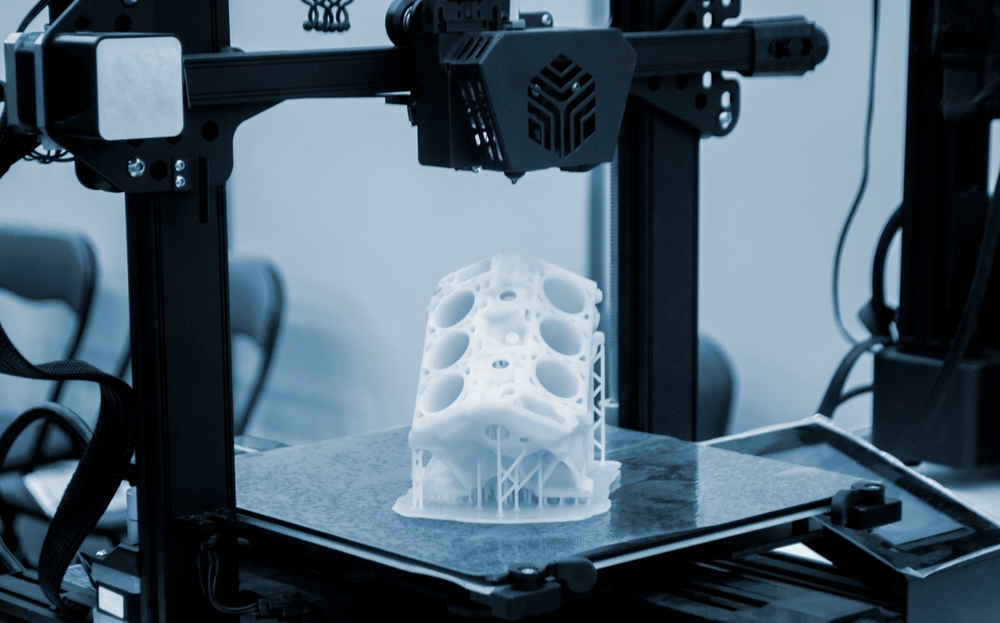

Enter 3D printing:

3D printing, also called additive manufacturing, is known as printing with parts added together. This is a big change that happened in the car-making business. Unlike the usual way that uses big machinery to take away material, 3D printing creates three-dimensional objects from digital pictures by adding layers. This new way lets us make car parts that are very special and detailed with the best accuracy.

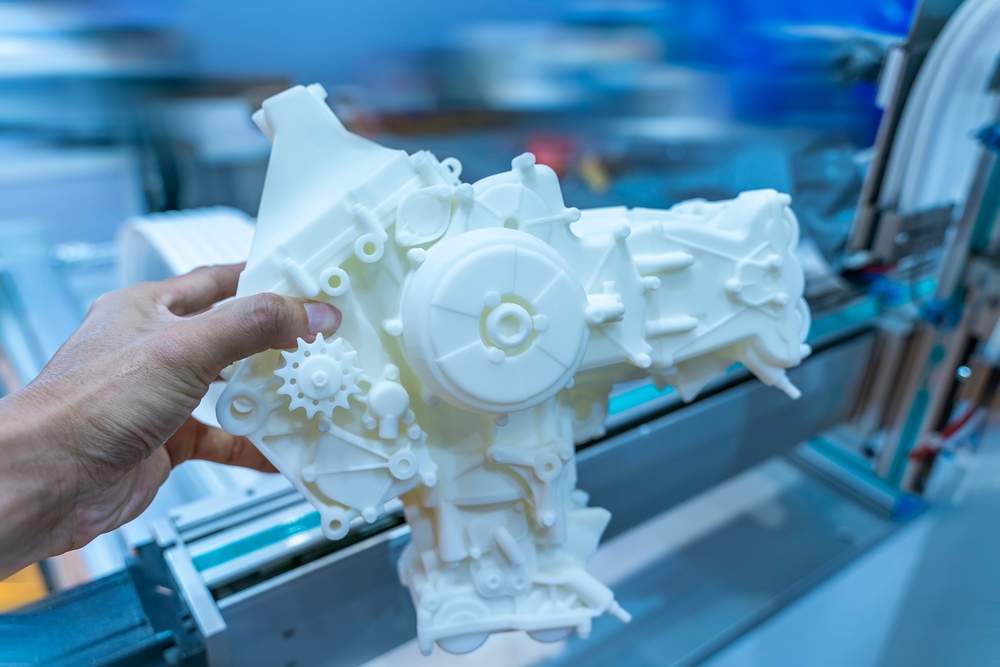

Customization Unleashed:

Making car parts for specific orders quickly is maybe the biggest good thing about 3D printing in the auto business. People who like cars and make them can now create custom parts for certain needs. This is a skill that both lovers of vehicles, or the makers, use to design things made only for special uses by individuals they want tailored to. With 3D printing, there are many more ways for you to have things made how you want them. This includes special body parts and unique inside items in a car or anything else. It’s really cool!

Reduced Time-to-Market:

Normal ways of making things often take a long time, from when they first think about what to make until the final item is sold. The making of things with 3D printers makes this timeline a lot less time-consuming. People who make car parts can quickly change and create new designs, then get them into stores very fast. This lets customers have unique pieces for their cars soon!

Cost-Efficiency and Waste Reduction:

3D printing makes the most of materials, cuts down on waste, and helps make things eco-friendly. Old ways often cause a lot of waste when using stuff, mostly when cutting or shaping things. Instead, 3D printing uses materials layer by layer to make objects and waste less. Moreover, the technology lets us use lightweight and modern materials. This helps in making vehicles weigh less and makes them more fuel-efficient too.

Complex Geometries and Lightweight Structures:

3D printing can do more than just make things custom. It also makes hard shapes that are tough or not possible to create with the old ways of making stuff in factories. This ability is very helpful when building lightweight structures to improve a vehicle’s speed. 3D printing lets engineers make fancy patterns and parts for cars. This leads to vehicles that work better and go faster.

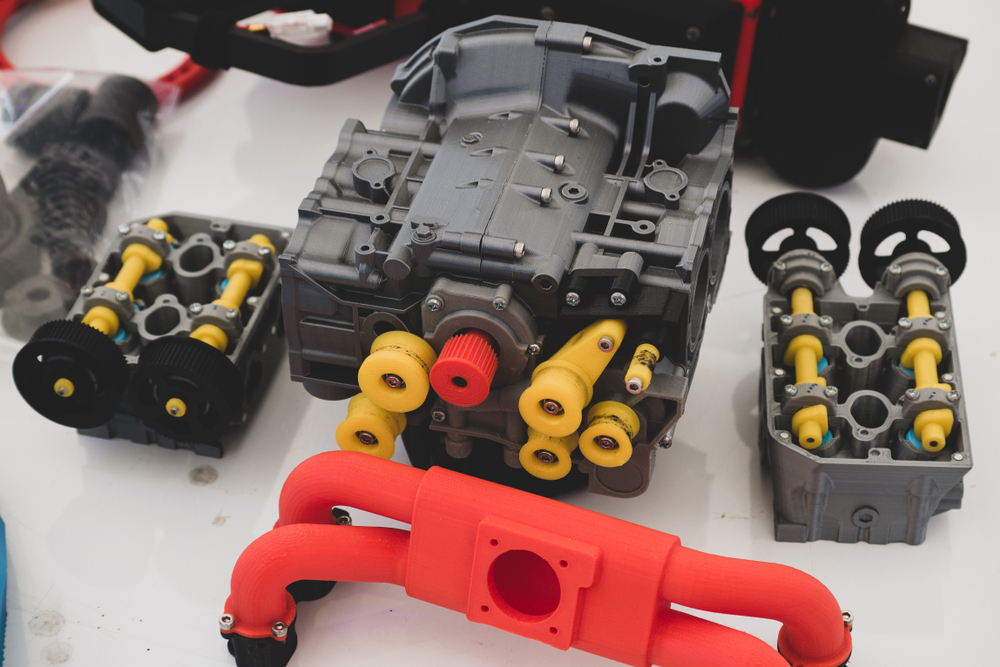

On-Demand Spare Parts Production:

The car business has always been trying to keep enough extra parts in stock for customers who need different things. 3D printing gives us a fix by letting us make extra parts when we need them. This not only lowers the demand for big piles but also makes sure old or hard-to-find parts can be made again as needed. This helps keep older cars going longer.

Material Innovation:

3D printing helps us use many kinds of stuff, like special mixes and strong plastics. This change in material use allows makers to adjust the features of car parts as needed for certain performance standards. If it’s about heat resistance, toughness, or making things lightweight, 3D printing helps engineers pick materials that match the special needs of every part.

Conclusion:

The importance of using 3D printing to make special car parts is huge. This technology is changing the way cars are made. It lets people make anything they want fast, cheaper, and easier, and it helps create hard yet easy-to-move car parts. As 3D printing changes and grows, we can expect a future where personalized vehicles that perform really well are not rare but usual. The time for making lots of custom cars where each car is different outside of the big companies has come, and 3D printing is leading to this change.