One of the most important challenges in automotive engineering is finding new and improved materials that are tailored for purpose. The materials used in today’s cars are essential factors that can shape the future of transportation by increasing overall fuel efficiency and improving safety standards. In this article, we’ll discuss some of the innovative developments in car materials that are transforming the industry.

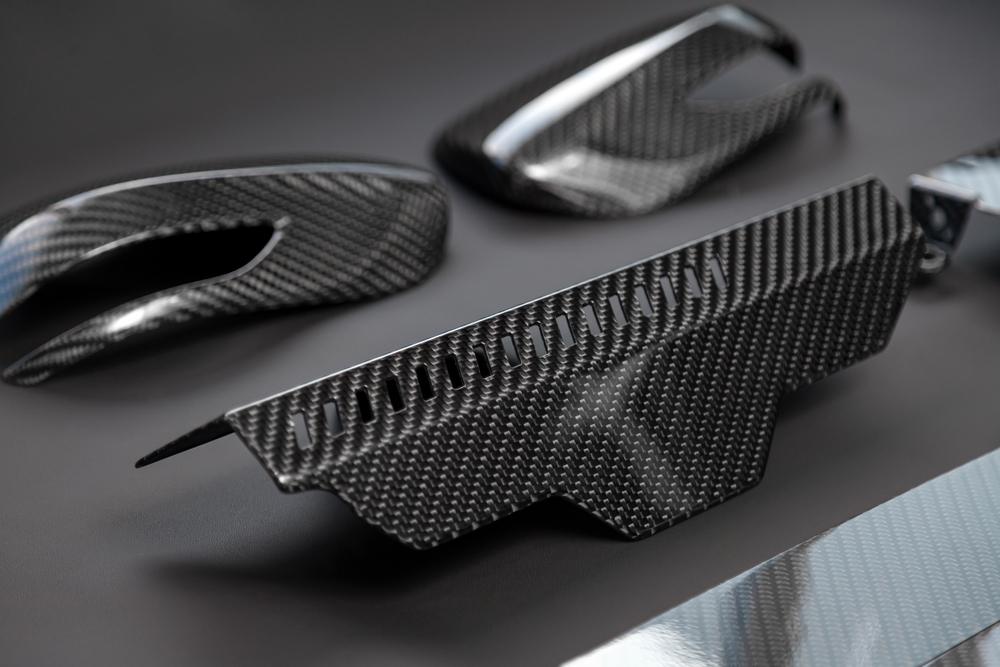

Carbon Fibre Reinforced Polymers (CFRP)

Carbon fibre is known as a wonder material in the automotive world for its outstanding strength-to-weight ratio. When used in combination with polymers, carbon fibre forms a composite material known as CFRP, which is light and tough. Unlike the usual steel, CFRP does not rust; therefore, it is a preferable alternative for manufacturers who want their vehicles to last longer.

Perhaps the greatest benefit of CFRP is its flexibility. Allowing designers’ creative freedom to create those sleek and effective car bodies that are both functional as well as attractive-looking. While CFRP is more costly to manufacture than steel or aluminium, recent developments in production are currently lowering costs, and this material can be used in mass-produced cars.

Advanced High-Strength Steel (AHSS)

For ages, steel has been used as an integral part in the manufacture of cars due to its high durability and cost-effectiveness. However, progress in metallurgy makes it possible to create AHSS, a promising new generation of steel with much greater strength without loss of formability. Combining various alloying elements and heat treatment processes, engineers can engineer the properties of AHSS to address specific performance needs.

AHSS provides many benefits in comparison to traditional steel, such as enhanced crashworthiness and weight savings, among others. The use of thinner gauges of AHSS in specific areas, such as the vehicle’s body structure, helps manufacturers realise significant weight savings while maintaining adequate safety standards. This ensures efficiency in fuel use and handling without compromising structural rigidity.

Aluminium Alloys

As weight reduction becomes a sought-after feature among car manufacturers, aluminium has become the preferred alternative to steel without compromising on strength. When compared to steel, aluminium alloys are more powerful per unit weight, and this is due to the fact that these properties make them a good material for body panels, chassis structures, and engine blocks.

Aluminium is highly recyclable, which gives it an edge in the environmental sustainability of car making. Even though aluminium alloys are often more expensive than steel, the benefits of reduced weight and increased fuel economy frequently outweigh these initial costs.

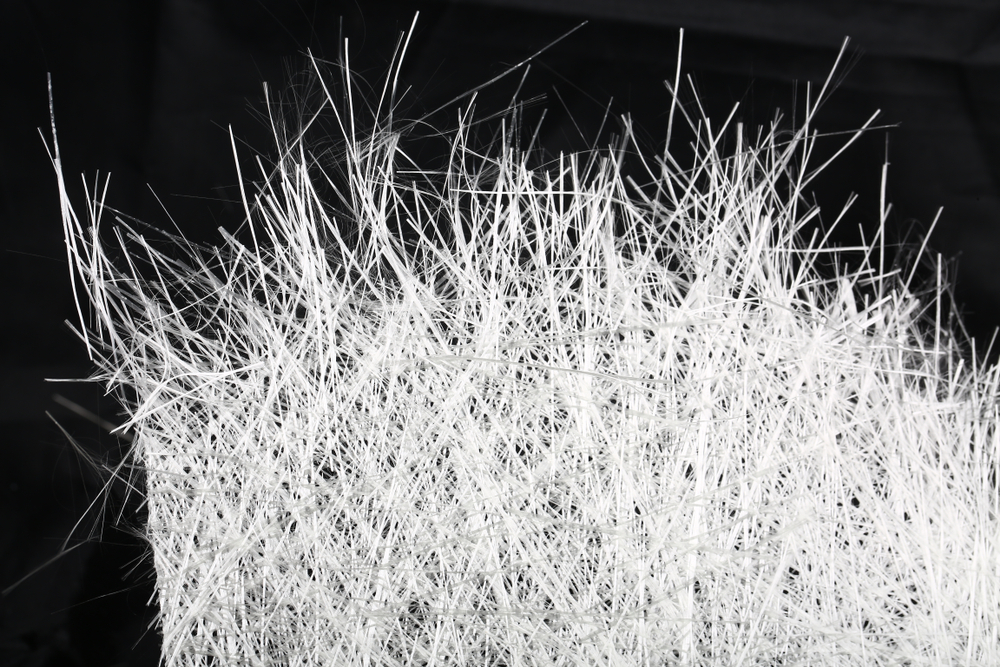

Composite Materials

Fibreglass and Kevlar, among the most widely used composite materials in automotive applications these days, are characterised by a unique blend of strength, toughness, and low weight. Such materials involve the matrix, most often a polymer resin system, and also fibres like glass or carbon.

Some of the benefits that composite materials have over traditional metals are resistance to corrosion and fatigue and the ability to be moulded into complex shapes. They also have the natural trait of lightness, which can lead to better fuel economy and performance. Despite the fact that composites initial cost is high as compared to steel or aluminium, their long-term advantages generally outweigh the investment.

Bio-based Materials

With sustainability becoming more integral to car manufacturing, bio-based materials are beginning to emerge as potential replacements for the long-used petroleum-based sources. These materials are from plants, agricultural waste, and recycled plastics, which are renewable sources.

Bio-based materials have a number of environmental advantages, such as an estimated reduction in carbon flows and reduced dependence on fossil fuels. They are suitable for various automotive uses, such as interior components, exterior panels, and insulation. Although bio-based materials have not become as widely used compared to other alternatives, continuous development is revealing tremendous potential.

In summary, the automotive sector is in a time of transformative change as manufacturers adopt new materials and methods of production to produce cars that are lighter, stronger, and more durable than ever before. The materials being used in modern cars are breaking the limits, from carbon fibre composites to advanced steel alloys. Technology has evolved over time, and we can only look forward to seeing greater developments that will shape the transport sector for decades to come.