Efficiency, performance, and sustainability are paths in the constant journey of automotive engineering development. When 2024 arrives, engine technology in the automotive industry will undergo a revolutionary change due to the pressures of regulations, consumer requirements, and technological advancements. In the engine room, engines are undergoing an amazing metamorphosis demonstrated by progress that redraw lines of power efficiency and ecological obligation.

Electrification Revolution:

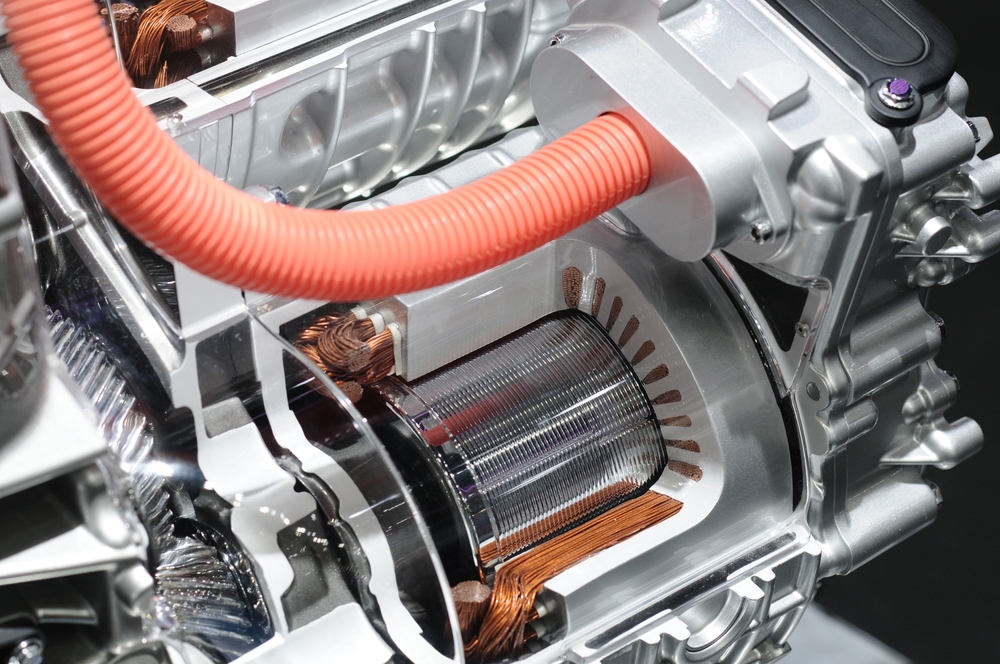

The electrification of powertrains for automobiles continues to be a leading point of innovation. In 2024, we will notice a significant increase in the implementation of electric vehicles (EVs) and hybrid electric vehicles (HEVs). Pure electric vehicles are on the rise as battery technology ages and charger facilities expand.

Furthermore, hybridization approaches are becoming more advanced to enhance efficiency and effectiveness. The use of mild-hybrid systems, which incorporate small electric motors to support the ICE, may improve fuel efficiency and emissions without compromising power.

Advanced Combustion Technologies:

With the introduction of highly improved combustion technologies, internal combustion engines undergo a revival. The direct injection systems, working in conjunction with turbocharging and variable valve timing, help ensure efficient fuel combustion, resulting in a higher level of power output as well as reduced emissions.

HCCI signifies a revolution in the technology of combustion. HCCI engines burning fuel through compression instead of spark ignition achieve better thermal efficiency and reduced emissions, making the distinction between gasoline and diesel difficult.

Enhanced Engine Materials:

The pursuit of more lightweight and stronger yet strong materials will stimulate the use of advanced materials. Traditional cast iron and steel are replaced by high-strength alloys, composite materials, and carbon fibre-reinforced polymers, which reduce their weight but increase structural strength.

Nanotechnology has various uses in engine coatings and lubricants, which serve to eliminate friction and abrasion between moving surfaces. Take the case of graphene-based lubricants, for example; these materials have high thermal conductivity and excellent frictional properties that prolong engine life while improving overall efficiency.

Digitalization and Predictive Maintenance:

Automotive engineering and digital technology are merging, paving the way for a predictive maintenance approach in which performance optimization is included. Engine parameters are monitored using the embedded sensors and on-board diagnostics that detect anomalies in real time while making predictions of potential failures before they occur.

Machine learning algorithms process millions of data points in real time to adjust engine performance and dynamically fine-tune fuel delivery, ignition timing, or other parameters according to driving conditions or driver input. In addition to increasing reliability, this active approach reduces maintenance costs and downtime.

Fuel Diversity and Alternative Propulsion:

The outpouring of diverse fuel options broadens the spectrum of engine technology, which is no longer confined to conventional gasoline and diesel. Biofuels are anthropogenic fuels such as ethanol and biodiesel that were used to replace the use of fossil fuels due to their failure to reduce emission rates and the elimination of dependency on a nonrenewable resource.

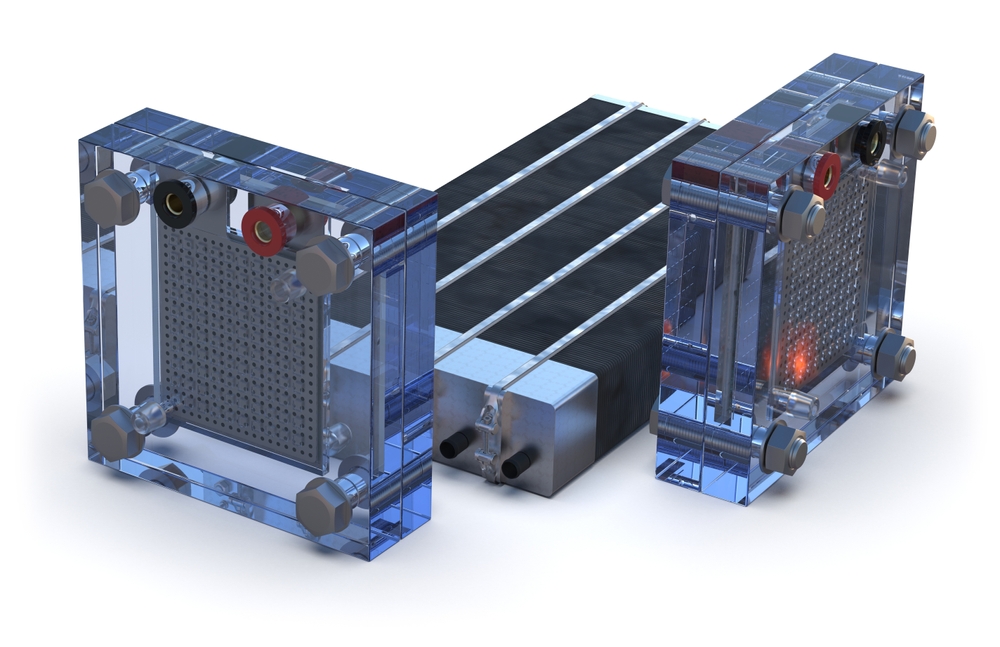

Hydrogen fuel cell technology emerges as a future zero-emissions engine. The electrochemical reaction between hydrogen and oxygen produced by the fuel cell to produce electricity only produces waste in the form of water vapor. With the growth of hydrogen infrastructure, FCEVs demonstrate their potential to transform long-distance travel while reducing ecological impacts.

Continued Embrace of Downsizing and Turbocharging:

This trend towards miniaturized, downsized turbocharged engines evolves as the automotive industry attempts to find an equitable compromise between power and efficiency. With reduced displacement and the mounting of turbochargers on them, engines resemble powerful engine competitors with low fuel consumption rates, producing lesser levels of pollutants.

In turn, variable-geometry turbochargers (VGT) refine the response of engine RPM across and make it possible to eliminate turbolag and improve drivability. Downsized turbocharged engines stand together with modern engine management systems as a combination of innovation and practical realism in current automobile engineering.

In all, by the year 2024, there will be a new paradigm in engine technology: electrification of advanced combustion, digitalization, and fuel diversification. Automotive engineers and researchers are innovating every single day in an attempt to combat both regulatory mandates and consumer tastes. Accordingly, an overall efficiency era under the bonnet is evoked. In tandem with the relentless engineering search for perfection, today’s engines are poised to usher in a new era of mobility that does not consume life on Earth.